Melform: most cost-effective refrigerated transport option

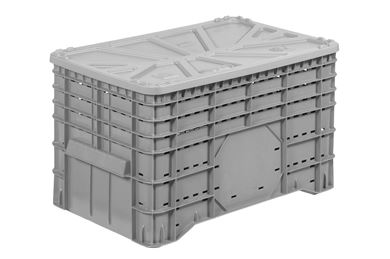

Transporting food is a complicated business. The cold chain must always be observed in order to provide a maximum guarantee of top-quality products. Refrigerated vehicles are a primary option for transporting high-volume products, but they are definitely not the only solution. Melform offers a wide range of portable refrigerated containers, ranging from small to large, so that you can even deliver food without refrigerating equipment in an ordinary car or van without disturbing the cooling-cycle.

Melform isothermalcontainers offer both innovative and cost-effective advantages.

Innovative:

- Manufactured according to rotomoulding technology, no corners or seams

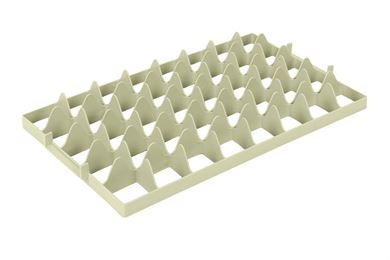

- Original construction for optimum loading

- No complete refrigerated or freezer vehicle/ installation can be kept at the right temperature

- Only pay for what you actually consume

- Combined goods shipment option (refrigerated / not refrigerated)

Cost-effective:

Melform isothermal containers are also the right choice from an environmentally friendly perspective. The units are completely recyclable when they are no longer operational.

Melform isothermal containers can be used for:

- F1 / F2 / F3

- Distribution services

- Food industry

- Small-scale production

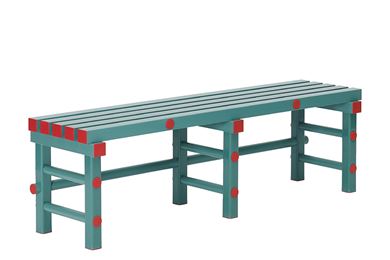

- Meal distribution

- Medical and laboratory transport operations (blood samples, vaccines, …)

- Refrigerated vehicle construction / equipment

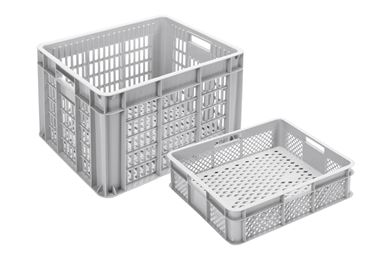

Melform isothermal containers are divided into 3 lines: Cargo Line, Koala Line and Koala Medical Line. Below is an overview of the differences for each line.

General:

Cooling:

external cooling elements

Power:

/

Structure*:

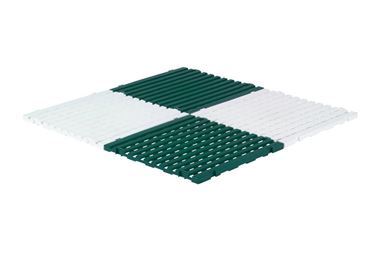

without wheels - with wheels - on feet - on pallet frame

Capacity:

132L - 1350L

T° usage:

-30°C to +75°C

T° control:

temperature control via eutectic plates

General:

Cooling:

integrated cooling equipment or cooling unit on top of appliance

Power:

socket 230V - car adapter 12V

Structure*:

without wheels - with wheels

Capacity:

cooling:68L – 1115L

freezing: 21L – 830LT° usage:

-30°C to +75°C

T° control:

cooling: 0°C to +10°C

General:

suitablefor the biomedical sector

Cooling:

integrated cooling equipment or cooling unit on top of appliance

Power:

socket 230V - car adapter 12V

Structure*:

without wheels - with wheels

Capacity:

T° usage:

-30°C to +75°C

T° control:

-25°C to +40°C

* Depending on the volume required