Melform Koala Line

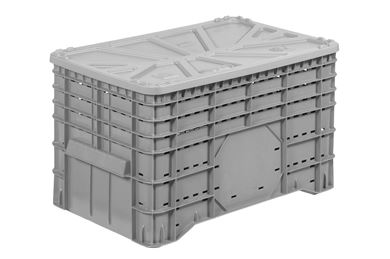

With the Melform Koala Line, you are choosing a proven, successful and efficient way to transport products at the right temperature. The Koala Line containers are manufactured in such a way that you can use them to transport products within the cold chain and actively keep these products at the correct temperature for several hours.

The active temperature maintenance system means that the containers are equipped with a cooling unit to maintain a constant temperature.

The design of the Melform Koala Line, manufactured in polypropylene using rotomoulding technology, guarantees efficient thermal insulation.

What can Koala Line isothermal boxes do for your transport?

The containers make it possible to distribute perishable goods without interrupting the cold chain. This can be done for goods that are warm, chilled or frozen. Each container is hermetically sealed to optimally protect the cold chain.

Depending on the customer's requirements, Melform containers can be equipped with RFID systems and USB data loggers for temperature recording and monitoring.

In which sectors can Koala Line containers be used?

Melform Koala Line containers enable the safe, reliable and time-independent storage and transport of all kinds of products, in particular pharmaceuticals, vaccines, blood derivatives, biotechnological products, transplants, serums and other sensitive goods. In the food sector, they are used in catering, ice cream parlours, patisseries, grill restaurants, vending machines and for the transport of artisanal products such as cold meats, meat and dairy products (cheese, milk, yoghurt).

Can I control the temperature?

Yes, the Koala Line is a range of isothermal containers equipped with a temperature control system. You can choose between an analogue system, which maintains a constant temperature, and a digital system, where you can set the temperature yourself. The Koala Line is equipped with a 230V AC connection and can also be plugged into vehicles at 12V.

Why do you recommend refrigerated transport?

Perishable products must be transported at the correct temperature. This guarantees the quality and safety of the products. The growth of unwanted bacteria is also prevented by transporting the goods within the correct temperature standards.

What types of Koala Line are there?

The Koala Line is divided into three types, which are subdivided according to temperature range.

- • from 0 °C to +10 °C

- • from -18 °C to +10 °C

- • from -25 °C to +40 °C

How can I move a Koala Line?

The Melform Koala Line models are available in various finishes. There are models on wheels or with a pallet frame. Depending on your working environment, you can choose the most suitable option. The operation of the Koala Line refrigerated containers remains unchanged.

What is the biggest advantage of isothermal bulk containers?

There are numerous advantages to choosing an isothermal bulk container. When it comes to transport, you have the great advantage of being able to carry out combined transports. The containers themselves can be perfectly combined with goods that do not require refrigeration. This significantly reduces the cost of refrigerated transport (e.g. using a refrigerated lorry). Even containers with different temperatures can easily be combined in the same vehicle.

Are Melform's isothermal containers environmentally friendly?

Yes. The isothermal containers are durable and can be used repeatedly. At the end of their life, they are 100% recyclable. They are made of polyethylene that is suitable for contact with food and insulated with polyurethane foam without CFCs or HCFCs.

The new “Koala Green” thermal accumulators are designed to deliver high performance while respecting the environment and guaranteeing energy savings.

What does rotomoulding technology mean?

Rotomoulding technology means that the containers are manufactured from a single piece. Both the container and the door consist of a single piece, without any welded parts.

Are there any certificates available for Melform isothermal containers?

Yes, the containers are certified according to ATP standards, NF standards and HACCP standards.